Maintaining commercial aircraft is a complex and demanding task. Airlines must ensure safety, comply with strict regulations, and keep operations efficient. Despite advances in technology, maintenance teams face numerous challenges that require expertise, planning, and coordination. Understanding these challenges highlights the difficulties of keeping commercial aircraft safe and reliable.

Complexity of Modern Aircraft

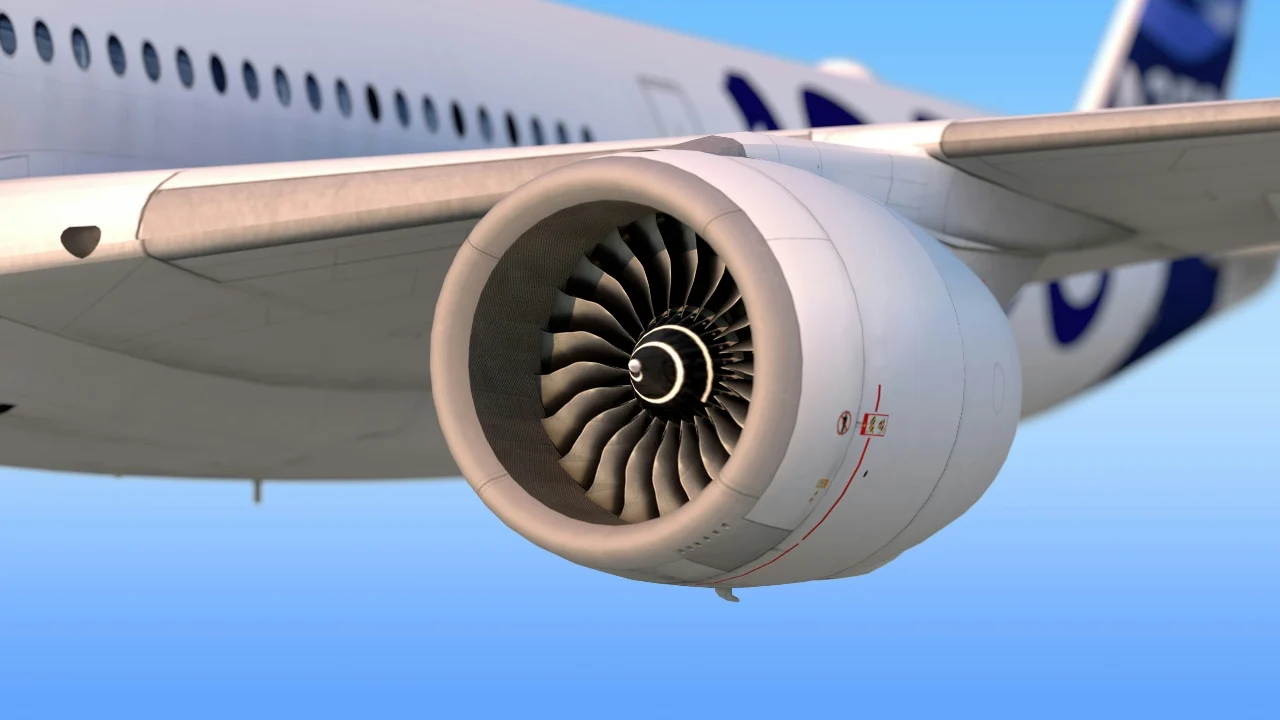

Modern commercial aircraft are highly sophisticated machines. They contain thousands of components, including advanced avionics, hydraulic systems, engines, and fly-by-wire controls.

This complexity makes maintenance more challenging. Technicians must understand intricate systems and ensure each part functions correctly. Even minor errors can lead to serious safety risks or operational disruptions.

Strict Regulatory Requirements

Aviation authorities, such as the FAA and EASA, impose rigorous maintenance regulations. Airlines must follow strict inspection schedules, document all maintenance activities, and comply with safety standards.

Meeting these requirements can be time-consuming and resource-intensive. Failure to comply can result in grounding of aircraft, fines, or license penalties, making regulatory adherence a critical challenge.

Wear and Tear from Continuous Operations

Commercial aircraft operate almost daily, often for long hours. This frequent use accelerates wear on engines, landing gear, hydraulics, and structural components.

Maintenance teams must perform inspections and repairs regularly to prevent failures. Managing the high volume of aircraft in service while ensuring each one is properly maintained is a constant challenge.

Supply Chain and Spare Parts Management

Aircraft maintenance requires a constant supply of parts and materials. Delays in spare parts delivery can postpone repairs and disrupt flight schedules.

Some aircraft models use specialized components that are difficult to source. Airlines must maintain efficient supply chains and inventory systems to minimize downtime and ensure operational reliability.

Skilled Workforce Shortages

Highly trained engineers and technicians are essential for effective maintenance. However, the aviation industry faces a shortage of qualified personnel in many regions.

Training new staff is time-consuming, and experienced technicians are in high demand. Shortages can lead to delays in inspections, increased workloads, and potential safety risks.

Technological Challenges

Modern aircraft rely on advanced systems such as digital avionics, automated diagnostics, and fly-by-wire controls. Maintaining these technologies requires specialized skills and equipment.

Technicians must continually update their knowledge and adapt to new tools. Integrating new technology while keeping older aircraft operational presents an ongoing challenge.

Cost Pressures

Aircraft maintenance is expensive. Airlines face the challenge of balancing safety and efficiency with operational costs. Extensive inspections, parts replacement, and skilled labor all add to expenses.

Cost pressures may tempt airlines to extend intervals between checks or delay non-critical repairs. However, safety regulations and operational risks prevent compromising maintenance standards.

Challenges Faced in Maintaining Commercial Aircraft

Environmental and Operational Constraints

Weather, airport infrastructure, and flight schedules can impact maintenance. Adverse weather may delay inspections or repairs, while limited hangar space can restrict access to aircraft.

Maintenance often needs to be performed within tight windows to minimize flight disruptions. Coordinating maintenance without affecting operations is a constant logistical challenge.

Conclusion

Maintaining commercial aircraft involves managing complexity, regulatory requirements, wear and tear, supply chains, skilled workforce shortages, technological demands, cost pressures, and operational constraints. Despite technological advancements, these challenges require expertise, careful planning, and dedication from engineers and technicians. Overcoming them ensures aircraft remain safe, reliable, and ready to serve passengers around the world.