Aircraft maintenance is essential for ensuring the safety and reliability of every flight. To manage this complex task, the aviation industry uses a structured system of scheduled maintenance checks, categorized as A, B, C, and D checks. Each type of check varies in scope, complexity, and frequency. Understanding these maintenance checks sheds light on how aircraft stay airworthy and safe over their service life.

A-Check: The Basic Routine Inspection

A-Check is the most frequent and routine type of inspection. Typically performed every 400-600 flight hours or approximately every 1-3 months, this check involves:

-

Visual inspections of key systems like landing gear, engines, and avionics.

-

Checking fluid levels, tires, brakes, and control surfaces.

-

Minor repairs and replacements of worn components.

A-Checks are usually done overnight or during short stops at airports, allowing quick turnaround times. Airlines use A-Checks to catch small issues early, maintaining aircraft readiness without disrupting flight schedules.

B-Check: More Detailed and Less Frequent

The B-Check is more thorough than the A-Check but less common in modern maintenance programs. It generally occurs every 6-8 months or about every 1,000 flight hours.

During a B-Check, maintenance crews perform:

-

More in-depth inspections of aircraft systems and structures.

-

Functional testing of avionics and emergency equipment.

-

Lubrication of parts and minor adjustments to mechanical systems.

Due to evolving maintenance strategies, many operators integrate B-Check tasks into A or C-Checks to streamline processes. When done, B-Checks still require aircraft downtime of several hours to a couple of days.

C-Check: Comprehensive and Intensive

The C-Check is a significant maintenance event, performed approximately every 18-24 months or after 4,000-6,000 flight hours. It involves:

-

Extensive inspection of the airframe, engines, landing gear, and control systems.

-

Checking for corrosion, cracks, and wear on structural components.

-

Removal and detailed examination of parts and systems.

-

Replacement or repair of components as needed.

C-Checks often require the aircraft to be taken out of service for 1-2 weeks. The process is labor-intensive and involves dozens or even hundreds of technicians. These checks are critical for ensuring long-term safety and compliance with regulatory requirements.

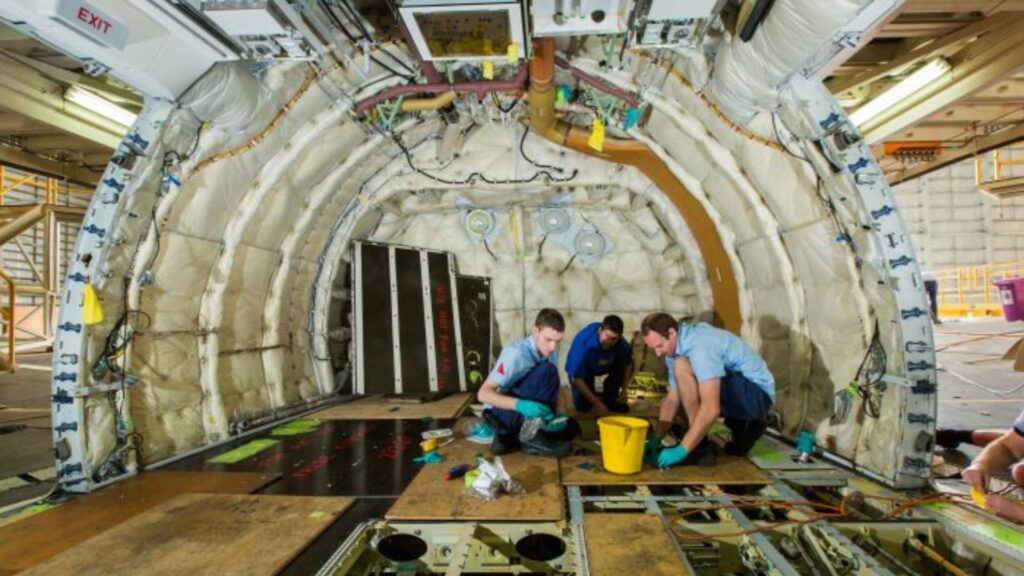

D-Check: The Most Extensive Overhaul

The D-Check, also called a “Heavy Maintenance Visit” (HMV), is the most comprehensive and demanding inspection. Typically conducted every 6-10 years, or after about 20,000 flight hours, the D-Check involves:

-

Complete disassembly of the aircraft’s major components.

-

Detailed inspection and overhaul of the fuselage, wings, engines, and landing gear.

-

Extensive structural checks, repairs, and upgrades.

-

Deep cleaning, corrosion control, and repainting.

D-Checks require the aircraft to be out of service for several weeks or even months, representing a substantial investment of time and money. Airlines carefully plan these checks to maximize aircraft lifespan and ensure compliance with the strictest safety standards.

Maintenance Schedule and Importance

Each of these maintenance checks fits into a broader, carefully planned schedule designed to maintain safety, reliability, and efficiency throughout an aircraft’s operational life. The checks progressively increase in complexity and depth, balancing the need to keep aircraft flying with ensuring thorough inspections.

Regulatory authorities such as the FAA and EASA mandate these checks as part of the Continuous Airworthiness Maintenance Program (CAMP), which all operators must follow to keep aircraft certified for flight.

Why These Checks Matter

Regular maintenance checks are crucial for:

-

Safety: Identifying potential faults before they become hazards.

-

Performance: Ensuring optimal operation of engines, avionics, and other systems.

-

Longevity: Extending the aircraft’s service life through preventive care.

-

Regulatory Compliance: Meeting aviation laws and standards to maintain certification.

Skipping or delaying these checks can lead to increased risk, unscheduled downtime, and higher costs from unplanned repairs or worse, accidents.

Conclusion

Understanding A, B, C, and D maintenance checks reveals the rigorous process behind every safe flight. From quick inspections to deep overhauls, these checks form the backbone of aviation safety, keeping aircraft airworthy and passengers secure.