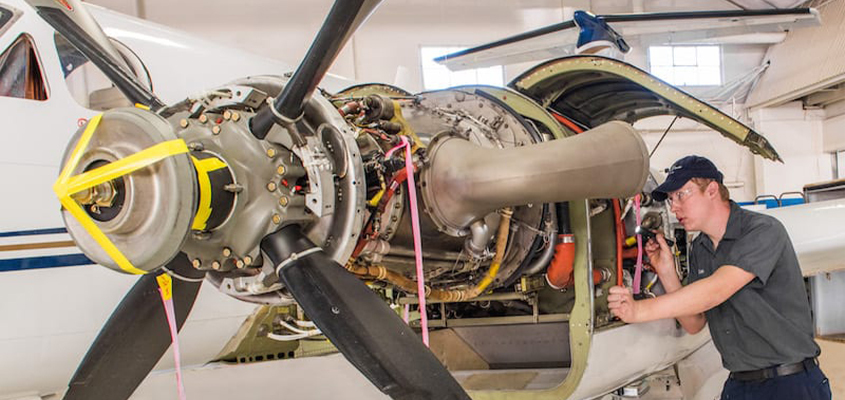

Engines are complex systems that demand consistent care. Whether you’re working with aircraft, heavy machinery, or automobiles, keeping your engine healthy ensures smooth operation, safety, and efficiency. These top engine maintenance tips will help you extend engine life, prevent major breakdowns, and maintain peak performance.

Follow the Manufacturer’s Maintenance Schedule

Every engine comes with a maintenance schedule based on time, hours of use, or mileage. Following it strictly is one of the simplest yet most effective ways to avoid mechanical issues.

What to do:

-

Stick to service intervals for oil, filters, and inspections

-

Log each maintenance task to track future needs

-

Schedule preventive checks even if the engine seems fine

Skipping scheduled maintenance can lead to expensive damage or voided warranties.

Monitor and Change Engine Oil Regularly

Engine oil lubricates internal components, reduces heat, and removes contaminants. Dirty or degraded oil increases wear and tear and can cause engine failure.

Maintenance tips:

-

Check oil levels before extended use

-

Change oil based on time or usage, not just mileage

-

Use the correct oil type and viscosity as recommended

Neglecting oil changes is one of the most common causes of premature engine wear.

Inspect and Replace Air Filters

Air filters keep dirt, dust, and debris from entering the combustion chamber. A clogged air filter reduces airflow, lowers fuel efficiency, and stresses the engine.

How to maintain:

-

Check air filters regularly, especially in dusty environments

-

Replace when visibly dirty or after the recommended interval

-

Use high-quality, OEM-compatible filters

Clean air means better combustion and a more efficient engine.

Maintain the Cooling System

Engines generate heat, and without proper cooling, they can overheat, warp, or seize. The cooling system—whether air or liquid-cooled—requires regular attention.

Key practices:

-

Check coolant levels and top off with the correct mixture

-

Inspect hoses, belts, and radiator caps for wear or leaks

-

For aircraft, ensure cowl flaps and baffles are unobstructed

An overheated engine often results in catastrophic damage. Prevention is simple.

Use High-Quality Fuel and Check for Contaminants

Fuel quality plays a major role in engine health. Dirty, stale, or water-contaminated fuel can cause poor performance or internal corrosion.

Tips to protect your fuel system:

-

Use only fuel from reputable sources

-

Drain sumps regularly in aircraft to check for water

-

Store fuel in clean, sealed containers away from moisture and sunlight

Poor fuel is a hidden risk that many overlook until it’s too late.

Inspect Ignition or Injection Systems

The ignition system is crucial for proper combustion. Worn-out spark plugs or faulty injectors can cause misfires, loss of power, or increased emissions.

Maintenance actions:

-

Inspect and replace spark plugs as recommended

-

Clean fuel injectors regularly if your engine uses them

-

Look out for hard starts, rough idling, or decreased fuel economy

A healthy ignition system ensures smooth, efficient operation.

Perform Routine Visual Inspections

Not all issues come with warning lights or alerts. A quick visual inspection can reveal leaks, frayed belts, loose connections, and other early-stage problems.

What to look for:

-

Oil, coolant, or fuel leaks under the engine

-

Cracks in hoses or loose clamps

-

Signs of corrosion, wear, or overheating

Spotting issues early can save thousands in repairs.

Top Engine Maintenance Tips

Check and Maintain Exhaust Systems

The exhaust system affects engine performance and emissions. Blocked or damaged components can reduce power and increase fuel use.

Tips for care:

-

Inspect mufflers, manifolds, and piping for cracks or leaks

-

Look for signs of soot or loud exhaust noises

-

Replace rusted or broken components promptly

A functioning exhaust system also protects you from harmful fumes.

Keep Engine Software and Sensors Updated

Modern engines rely on sensors and electronic control units (ECUs). These systems need calibration and occasional updates to maintain precision.

Best practices:

-

Use diagnostic tools to check for fault codes

-

Update software during major services or when advised

-

Calibrate sensors after component replacements

Ignoring electronic issues can lead to poor performance or emissions failures.

Track All Maintenance Activities

A well-maintained logbook or digital tracking system makes it easy to manage service intervals and repairs. This is especially vital in aviation and commercial operations.

What to record:

-

Date of service and engine hours or mileage

-

Tasks performed and parts replaced

-

Technician’s name and certification (if applicable)

Detailed records improve resale value, ensure compliance, and support warranty claims.

Don’t Ignore Warning Signs

Strange noises, smells, or changes in engine behavior often signal deeper issues. Early diagnosis saves time and money.

Watch out for:

-

Unusual knocking or rattling

-

Smoke from the exhaust

-

Sudden drops in power or acceleration

-

Warning lights or error codes

Responding early helps prevent breakdowns and expensive overhauls.

Conclusion

Engine maintenance isn’t just about fixing problems — it’s about preventing them. These top engine maintenance tips give you the tools to protect your investment, improve performance, and keep operations safe and efficient. Whether you manage aircraft engines or heavy-duty vehicles, consistency and attention to detail are the keys to long engine life.