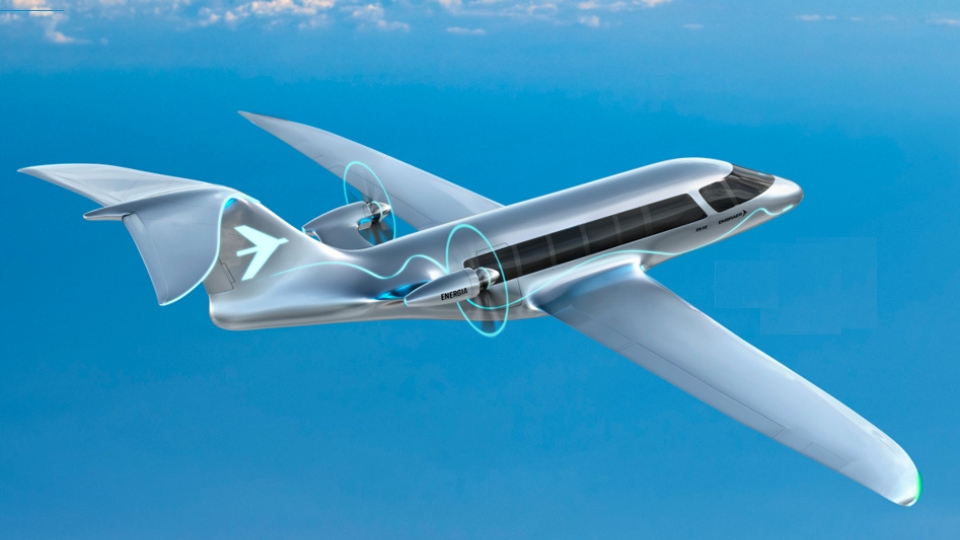

Building an aircraft is one of the most complex engineering feats in modern manufacturing. It requires thousands of skilled professionals, precision technology, and global coordination. From a simple sketch to the roar of engines on the runway, let’s break down the steps that transform a blueprint into a flying machine.

Design & Concept Development

Every aircraft begins with a need—more passengers, better fuel efficiency, longer range. Engineers and designers gather input from airlines, regulatory bodies, and market trends. Using advanced software like CAD (Computer-Aided Design) and CFD (Computational Fluid Dynamics), they create detailed digital models that simulate aerodynamics, structural integrity, and performance.

Design teams also run wind tunnel tests on scale models to validate airflow and reduce drag. Once the design proves sound, the concept moves into the planning phase.

Engineering & Certification Planning

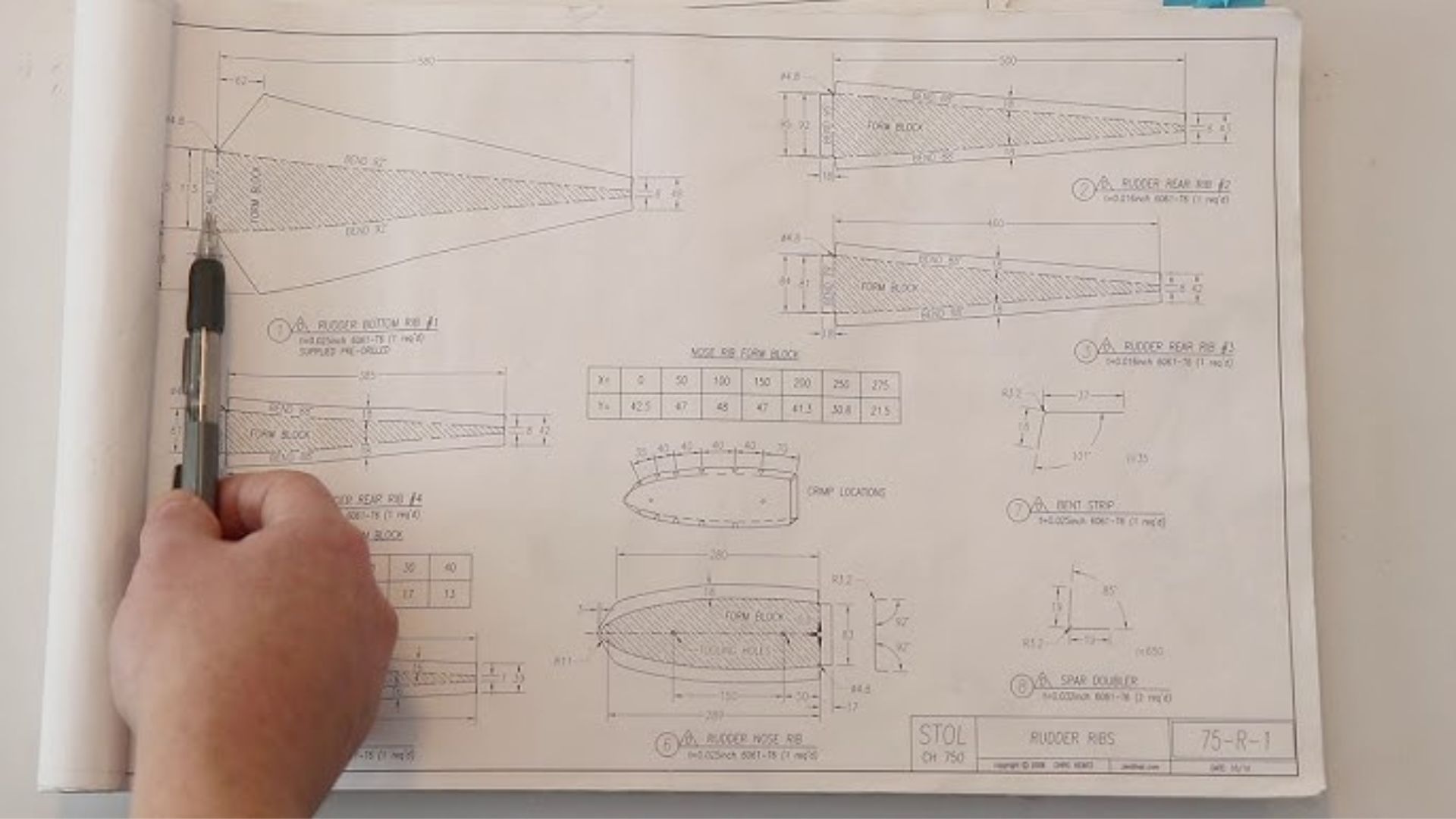

Once the aircraft’s basic design is finalized, engineers focus on specifics: structural components, materials, propulsion systems, avionics, and cabin layout. Every single part must meet strict aviation safety regulations set by agencies like the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency).

Before any construction begins, the manufacturer submits design documentation for certification. It’s an intensive process, requiring thorough testing and risk analysis.

Manufacturing Major Components

Aircraft manufacturing is modular. The plane is split into large sections such as:

-

Fuselage (body)

-

Wings

-

Tail assembly (empennage)

-

Landing gear

-

Engines

-

Cockpit and avionics systems

These components are often built at different factories around the world. For example, Airbus manufactures the A350’s wings in the UK, fuselage sections in Germany, and final assembly in France. Boeing sources parts for the 787 Dreamliner from Italy, Japan, and the U.S.

Precision machinery, robotics, and human craftsmanship come together in specialized facilities where each component is built to exact tolerances.

Final Assembly

Once all major parts arrive at the Final Assembly Line (FAL), technicians begin to piece the aircraft together. This phase includes:

-

Joining fuselage sections

-

Attaching wings and tail

-

Installing landing gear

-

Integrating engines

-

Wiring avionics and control systems

-

Outfitting the cabin

Ground & Flight Testing

Before the aircraft can take to the skies, it must pass a rigorous ground test phase. Engineers test hydraulics, electrical systems, avionics, and fuel lines. Pressure tests simulate altitude conditions to check for cabin integrity and system reliability.

After ground testing, test pilots conduct flight tests to evaluate:

-

Engine performance

-

Handling and control response

-

Stall behavior

-

Landing gear operations

-

Emergency systems

These tests verify that the aircraft meets all safety and performance standards required for certification.

Certification & Delivery

Once the aircraft passes all flight tests and inspections, aviation authorities issue airworthiness certificates.

At this point, the customer airline performs its own acceptance procedures, including final checks and training sessions for pilots and crew.

First Flight & Entry Into Service

Finally, the aircraft rolls out for its first official flight with passengers—marking the end of a multi-year journey from drawing board to the sky. Airlines may use this flight as a media event, showcasing the new addition to their fleet.

Conclusion

Building an aircraft involves cutting-edge engineering, massive coordination, and meticulous attention to detail. From the initial blueprint to the moment it lifts off the runway, every stage is critical. This intricate process ensures that every aircraft is not only safe but also efficient and reliable for years of service in the skies.