Aircraft design has come a long way since the Wright brothers’ first flight in 1903. From simple, fragile structures to today’s advanced, aerodynamic jets, every stage of development has pushed the boundaries of innovation. This article explores the key milestones that define the evolution of modern aircraft design.

Early Designs: Wood, Fabric, and Trial by Error

The earliest aircraft featured lightweight wooden frames covered in fabric. Designers prioritized lift over durability. The Wright Flyer, for instance, used a 12-horsepower engine and hand-carved propellers. It barely left the ground, but it proved that powered flight was possible.

These primitive aircraft lacked stability and control, which limited their range and safety. Pilots flew at their own risk, and many designs failed to gain traction due to structural limitations.

The Age of Metal: Strength Meets Speed

By the 1930s, engineers began replacing wood with metal—primarily aluminum. This shift marked a turning point in aircraft design. Metal airframes allowed for sleeker shapes and greater durability. Planes could now fly faster, higher, and farther.

World War II further accelerated innovation. The Boeing B-17 and Supermarine Spitfire introduced streamlined fuselages, retractable landing gear, and more efficient wing designs. Aircraft designers focused heavily on aerodynamics, which directly influenced post-war commercial aviation.

Jet Engines and the Shape of the Future

The introduction of the jet engine in the 1940s revolutionized aircraft design. Designers no longer needed propellers, which changed the shape of aircraft entirely. Swept wings, thinner fuselages, and pressurized cabins became standard features.

Commercial aviation embraced jets with open arms. The Boeing 707 and Douglas DC-8 ushered in the Jet Age, offering faster and smoother flights. Aircraft became more efficient as designers learned to optimize airflow, reduce drag, and improve fuel consumption.

Materials Revolution: Composites and Carbon Fiber

In the 21st century, materials science has become a central part of aircraft design. Modern aircraft like the Boeing 787 Dreamliner and Airbus A350 rely heavily on composite materials. Carbon fiber-reinforced polymers are lighter and stronger than traditional aluminum.

These materials reduce aircraft weight, which improves fuel efficiency and lowers emissions. Designers can now build larger aircraft that remain nimble and cost-effective. The use of composites also extends an aircraft’s service life and reduces maintenance.

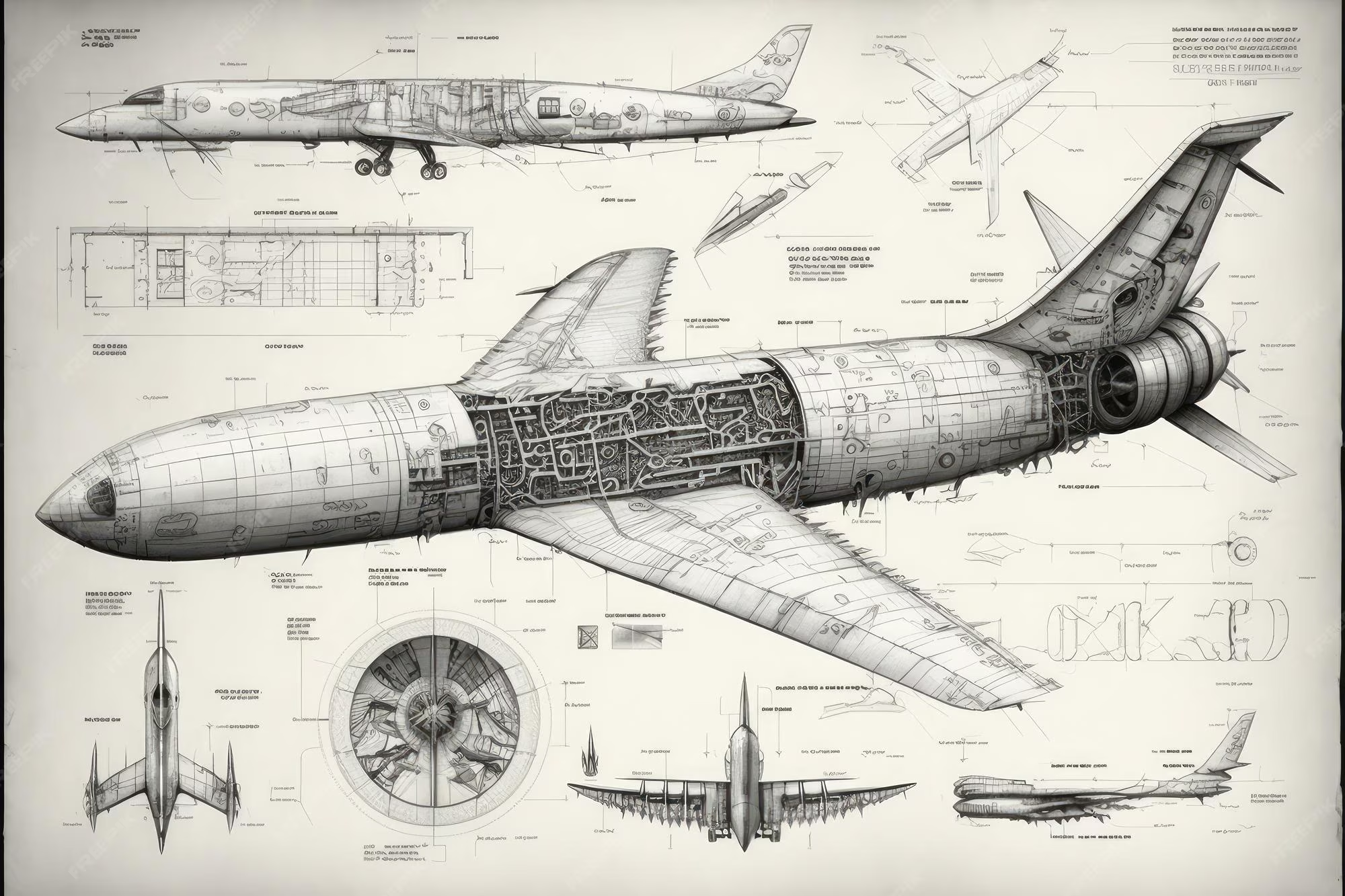

Digital Design and Aerodynamic Modeling

Advanced computer simulations have transformed the design process. Engineers now use computational fluid dynamics (CFD) to model airflow over wings and fuselage shapes before building a single part. These simulations allow for precise adjustments that reduce drag and increase lift.

Digital twins and 3D printing have also entered the scene. Designers can quickly prototype components and test them virtually, cutting down on development time and cost.

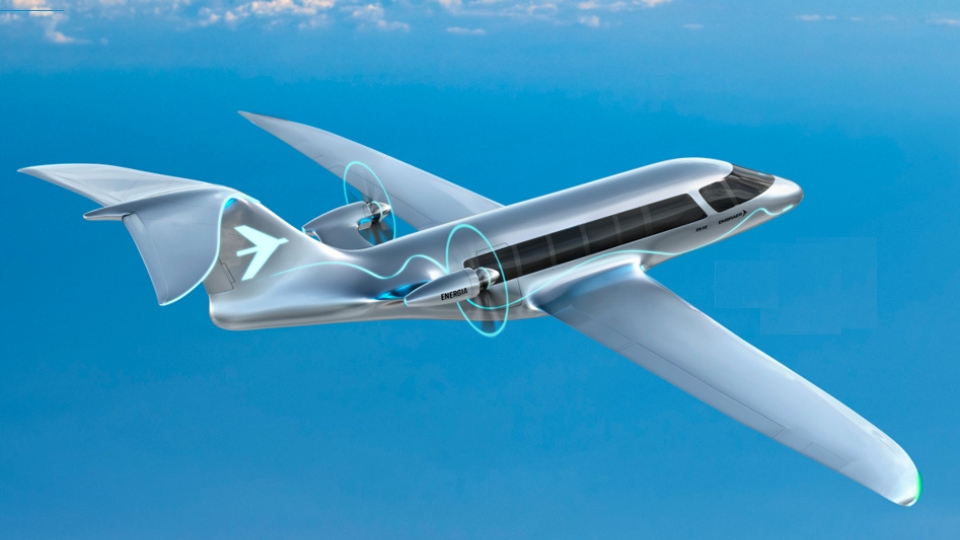

Looking Ahead: Electric and Sustainable Aircraft

Modern aircraft design is moving toward sustainability. Electric and hybrid propulsion systems are being tested worldwide. These systems promise to cut fuel use and carbon emissions dramatically.

Designers are experimenting with novel shapes, such as blended wing bodies and vertical take-off and landing (VTOL) aircraft. These futuristic concepts aim to improve efficiency and solve problems like airport congestion and noise pollution.

Conclusion

The evolution of modern aircraft design reflects a relentless pursuit of efficiency, safety, and sustainability. From fragile wooden frames to composite-built marvels powered by jet engines, aircraft design has continuously adapted to meet the needs of modern aviation. As we move into an era of electric propulsion and autonomous systems, the future of aircraft design looks more exciting than ever.