Keeping accurate, auditable aircraft logs protects safety, ensures regulatory compliance, and speeds troubleshooting. Whether you manage a single business jet or a fleet, this guide gives clear, actionable steps to track aircraft logs effectively — from paper logbooks to modern digital systems.

Why good log tracking matters

First, good logging creates a dependable history of the aircraft’s condition, maintenance, and modifications. Second, it supports airworthiness decisions, warranty claims, and resale value. Finally, it simplifies audits and reduces the risk of missed inspections or Airworthiness Directives.

Types of aircraft logs you should track

-

Airframe logbook (structural hours, damage history)

-

Engine and APU logbooks (cycles, on-condition events, removals)

-

Component/rotable logbooks (life-limited parts, serial numbers)

-

Maintenance release and work-order records (who did what and when)

-

Scheduled inspection records (inspections, borescope, eddy-current)

-

Software and avionics configuration logs

-

Flight data and service bulletins/Airworthiness Directives (AD) compliance

-

Fuel and oil consumption logs (for troubleshooting/perf analysis)

Step-by-step process to track aircraft logs

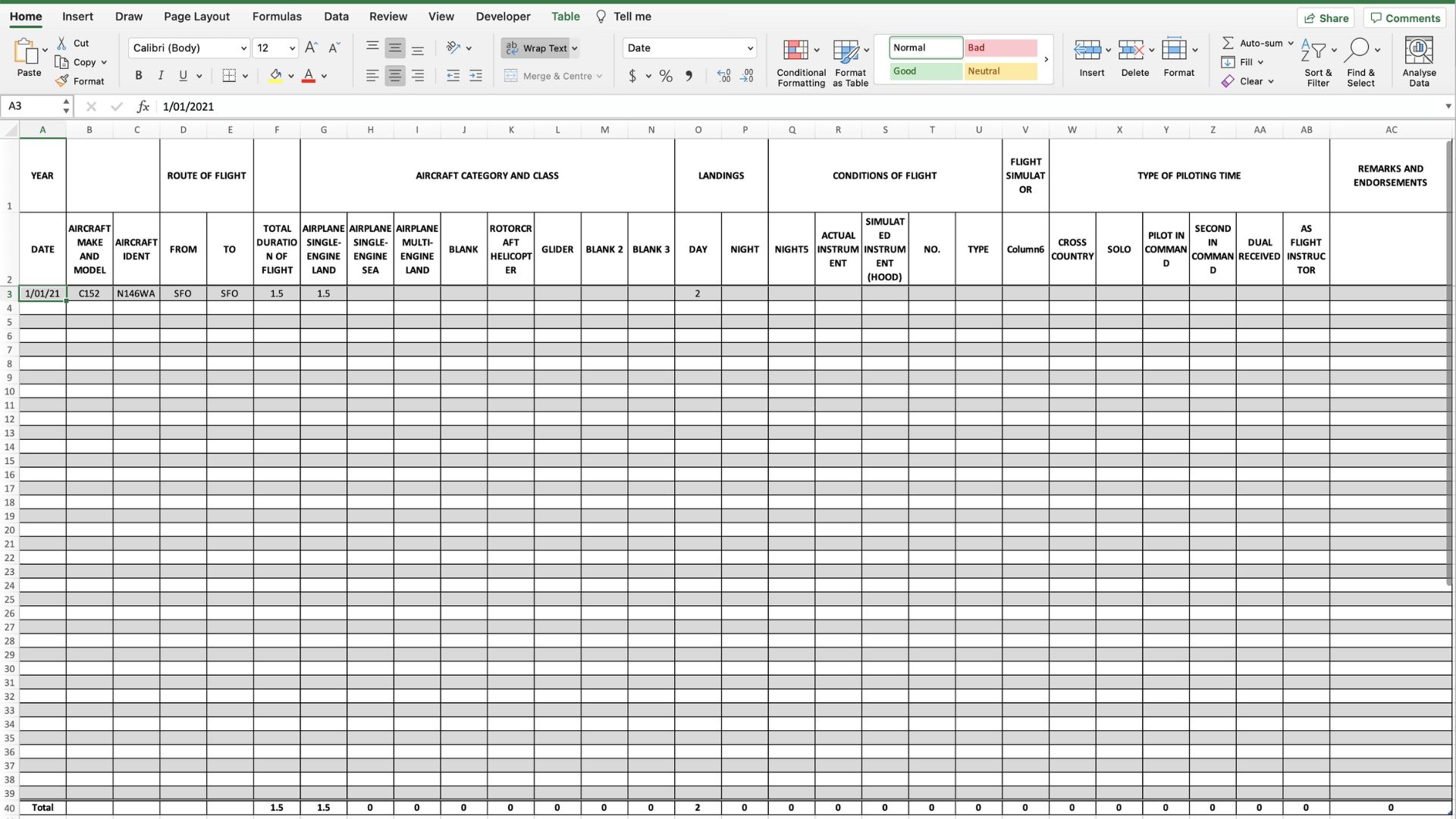

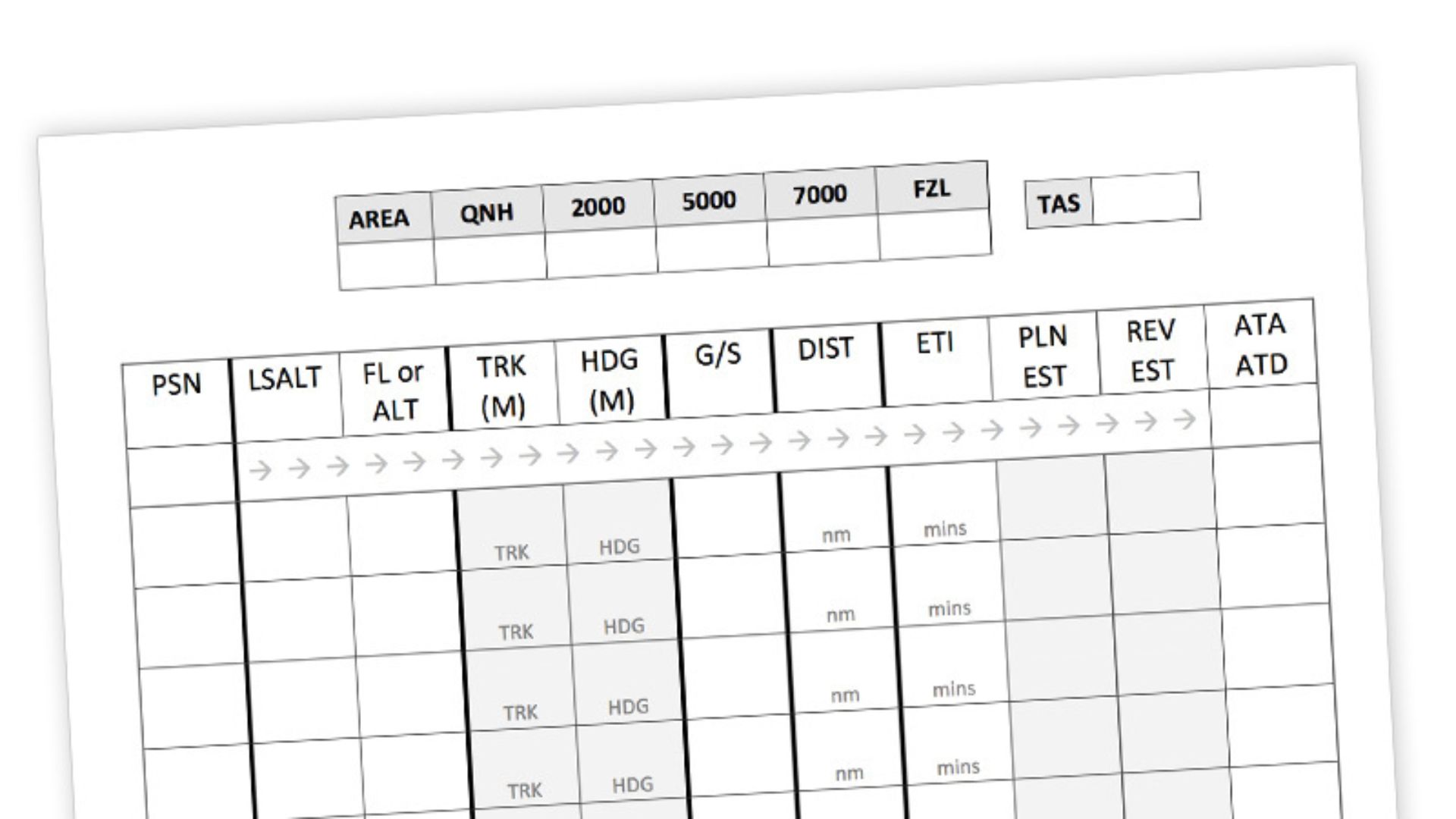

1. Define required records and format

Decide which log types you must keep and the minimum fields for each entry. Standard fields include date/time, aircraft registration, component serial number, flight hours/cycles at event, description of work, references (work order or AD number), signature and certifying staff credentials.

2. Choose a tracking method

You have two main choices:

-

Paper/manual logbooks — simple and legally accepted in many jurisdictions, but harder to search and back up.

-

Electronic/maintenance tracking system (MRO software) — enables searchability, cross-referencing, automated reminders, and secure backups. Electronic systems often integrate with flight logs and parts inventory.

3. Standardize data entry rules

Set rules so every technician and pilot records data consistently:

-

Use ISO date format (YYYY-MM-DD) or your company standard

-

Record decimal hours for flight time (e.g., 123.7 hrs)

-

Use pre-defined action codes (e.g., INS for inspection, REP for repair)

-

Require a signature and certificate number for release-to-service entries

4. Link logs to work orders and parts

Always associate each log entry with a work order and any part serial numbers used. This creates traceability from defect to corrective action to replacement part.

5. Implement versioning and time-stamps

In digital systems, enable immutable time‑stamping and version history so you can see who changed an entry and when. For paper logs, never erase: strike through errors, initial the correction, and add an explanatory note.

6. Set retention and backup policies

Define how long you will retain logs (many operators keep them for the aircraft’s life). Digitize paper logs and maintain off-site backups. Test your restore process periodically.

7. Create automated alerts

Use calendar or MRO system alerts for upcoming inspections, life-limited part removals, and AD compliance windows. Alerts reduce human error and missed deadlines.

8. Audit and reconcile regularly

Schedule monthly reconciliations between flight logs, engine hours, and maintenance records. Perform internal audits quarterly and correct any discrepancies immediately.

How to Track Aircraft Logs

Key fields for every log entry (template)

-

Date/time

-

Aircraft reg / serial number

-

Component / engine serial number (if applicable)

-

Hobbs / flight hours / cycles at event

-

Description of defect or maintenance action

-

Work order number

-

Parts used (PN/SN)

-

Certifying technician name and license number

-

Release to service (Y/N) and signature

-

References (AD, SB, maintenance manual chapter)

Best practices and tips

-

Train staff on the importance of complete, accurate entries — human habit beats software features.

-

Maintain a single source of truth: pick one primary system (paper or electronic) and avoid divergent copies.

-

Protect records with access controls and audit logs; only authorized personnel can sign or modify entries.

-

Use structured dropdowns in electronic forms to avoid spelling errors and inconsistent terminology.

-

Capture photos when applicable (damage, installations); link images to log entries.

-

When transferring aircraft between operators, prepare an indexed log package to speed handover and preserve value.

Troubleshooting common issues

-

Missing hours/cycles: Reconcile flight logs, airplane-mounted hour meters, and engine records immediately. If gaps remain, document the investigation and corrective steps.

-

Conflicting entries: Create an audit note explaining the conflict, identify the authoritative source, and correct following your procedures.

-

Lost paper logbook: Treat as a serious event; reconstruct records using flight manifests, maintenance invoices, and digital backups. Notify regulators if required.

Security and compliance considerations

Protect personal data and commercially sensitive information within log systems. Comply with your country’s aviation authority rules for record retention and release-to-service statements. When in doubt, consult your accountable manager or regulatory advisor.

Quick checklist to start tracking better today

-

Define mandatory log types and fields

-

Pick and configure a primary tracking system

-

Standardize entry formats and implement staff training

-

Link every log entry to work orders and parts

-

Enable backups, alerts, and periodic audits

Conclusion

Accurate aircraft log tracking reduces risk, speeds maintenance, and preserves asset value. By standardizing entries, adopting an appropriate tracking system, linking work orders and parts, and auditing regularly, you create a reliable, auditable history that supports safe operations. If you want, I can produce a printable log-entry template or suggest a step-by-step rollout plan for implementing a digital tracking system for your fleet. Which would help you most?