Commercial aircraft stand among the most advanced machines ever created. Every part of their design focuses on one goal—achieving maximum performance and efficiency. Engineers combine precision, innovation, and rigorous testing to ensure each plane flies safely and economically. From materials to engines, every element contributes to exceptional performance in the air.

How Commercial Aircraft Are Built for Performance

The Power of Aerodynamic Design

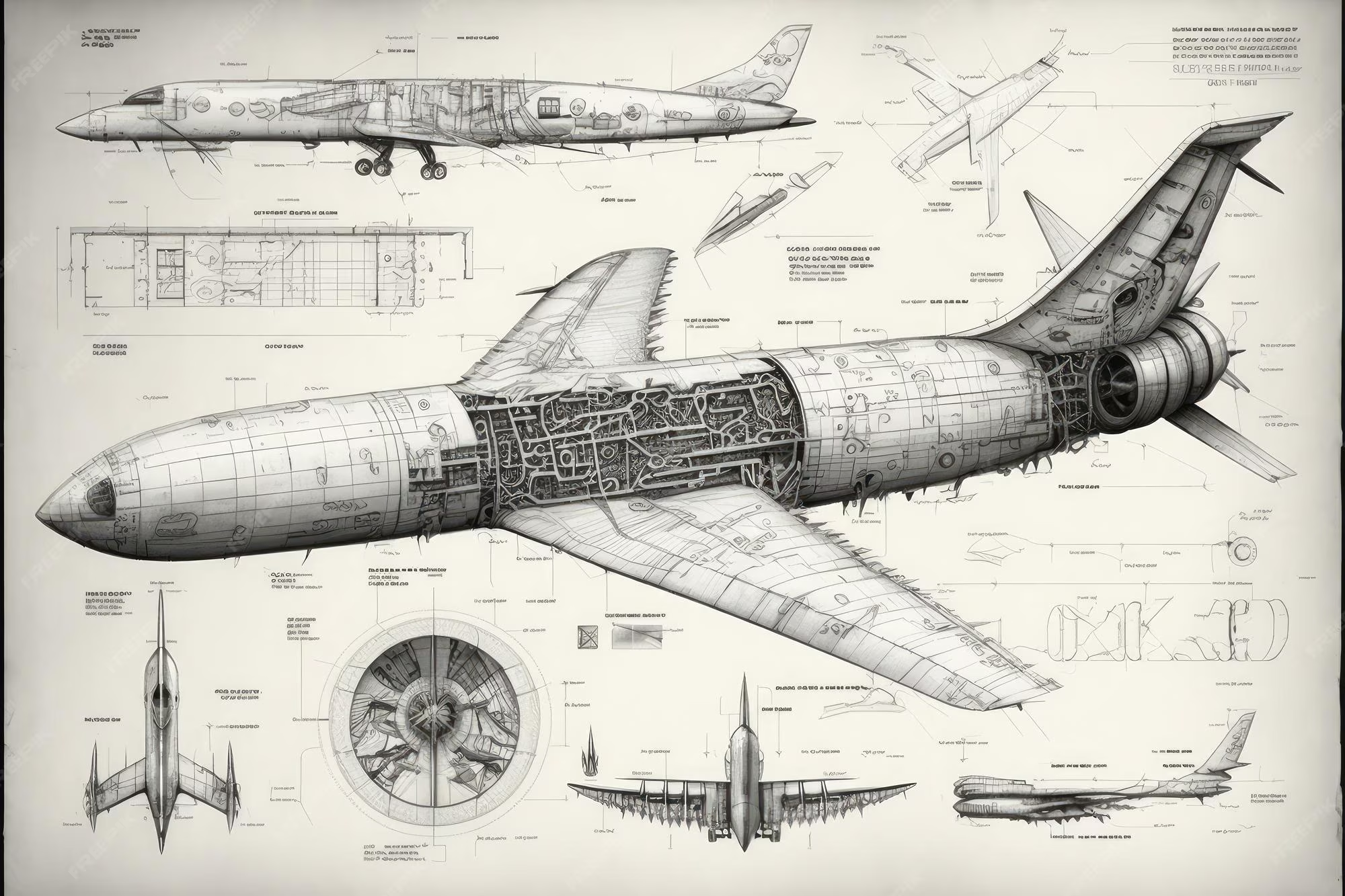

Aerodynamics plays a central role in aircraft performance. The shape of the fuselage, wings, and tail is carefully engineered to reduce drag and improve lift. Smooth contours allow air to flow efficiently around the body, minimizing resistance and saving fuel.

Modern aircraft feature winglets at the tips of their wings. These curved extensions decrease turbulence, improving stability and fuel economy. As a result, airlines can reduce emissions while maintaining high cruising speeds. Engineers also use computer simulations to test various designs before production, ensuring each aircraft performs flawlessly in real-world conditions.

Lightweight Materials That Strengthen Efficiency

Weight directly impacts how an aircraft performs. The lighter the plane, the less fuel it needs. To achieve this balance, manufacturers use advanced materials such as carbon-fiber composites and titanium alloys.

Composites offer strength without unnecessary bulk. They also resist corrosion, reducing maintenance costs. Aluminum, once the primary material in aircraft, now shares space with these modern alternatives. Each part of the aircraft — from fuselage panels to interior fittings — is designed to optimize strength while keeping weight low.

Furthermore, material science continues to evolve. Engineers constantly test new compounds to find lighter yet more durable solutions. Every gram saved contributes to higher speed, longer range, and lower fuel consumption.

Powerful and Efficient Engines

Engines are the heart of any commercial aircraft. Today’s jet engines are built for both speed and efficiency. Manufacturers focus on designs that deliver maximum thrust with minimal fuel burn.

Turbofan engines dominate commercial aviation because of their power and reliability. They work by compressing air, mixing it with fuel, and igniting the mixture to produce thrust. Advanced turbines, fan blades, and compressors increase airflow and reduce noise levels.

Engineers also rely on digital control systems to monitor performance in real time. These systems adjust engine output for changing flight conditions, improving safety and economy. Consequently, modern aircraft can travel farther while consuming less fuel than ever before.

Smart Use of Technology in Construction

Technology plays an essential role in every stage of aircraft manufacturing. Computer-aided design (CAD) allows engineers to visualize components with incredible precision. Automated assembly systems then build these components with exact measurements, ensuring consistency and quality.

Sensors installed throughout the aircraft collect data during testing. Engineers analyze this information to identify weak points and improve future models. Virtual reality tools even allow design teams to walk through digital prototypes before physical production begins.

Because of these technological advancements, manufacturing time has decreased while accuracy has improved. Each aircraft rolls out of the factory stronger, faster, and more efficient than the last generation.

Testing for Safety and Performance

Before entering service, every commercial aircraft undergoes extensive testing. Engineers simulate extreme conditions to confirm that the plane can withstand stress, pressure, and vibration. Wind tunnels evaluate aerodynamic performance, while flight tests confirm handling and balance.

Engines also face separate endurance trials to ensure reliability. Pilots, technicians, and engineers collaborate to identify even minor flaws. Only after meeting all international safety standards does an aircraft receive certification for commercial use.

These procedures guarantee that every plane not only performs well but also ensures passenger safety at every altitude.

Environmental Performance and Fuel Efficiency

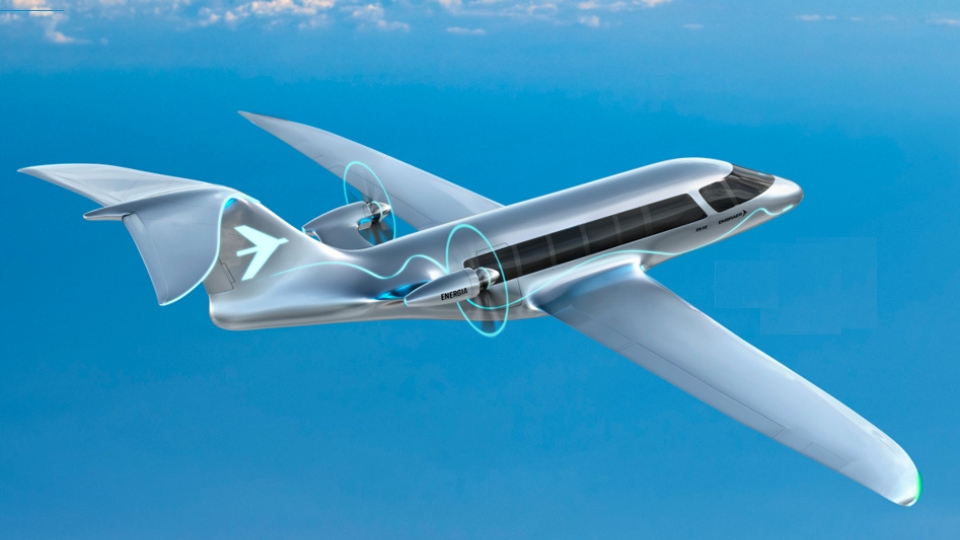

Sustainability has become a major focus in modern aviation. Manufacturers continuously explore ways to reduce fuel usage and emissions. Aerodynamic improvements, hybrid engines, and alternative fuels all play a role in making air travel greener.

Electric and hydrogen-powered aircraft are currently in development. Though still in testing stages, they promise to revolutionize commercial flight by cutting carbon output drastically. Airlines also participate by using eco-friendly operational practices such as efficient flight routes and lighter onboard equipment.

Through these collective efforts, aviation moves steadily toward a more sustainable future without sacrificing performance.

The Future of Aircraft Engineering

Innovation never stops in the aviation industry. Engineers are developing smarter materials, AI-driven flight systems, and even fully autonomous aircraft. Future planes will likely be faster, quieter, and more energy-efficient.

Designers also aim to enhance passenger comfort while improving operational efficiency. With ongoing research, the next generation of aircraft may achieve near-zero emissions while maintaining top performance.

Sports Online – Wings of Alaska

WingsOfAlaska.com provides aviation tours and adventure experiences in Alaska. Travelers also explore sports online for interactive online engagement. It adds excitement to adventure planning.

Conclusion

Building a commercial aircraft requires precision, innovation, and relentless testing. From aerodynamic design to lightweight materials, every component contributes to performance and efficiency. Modern technology continues to push boundaries, creating safer and greener planes each year.

Ultimately, these engineering achievements ensure that commercial aircraft not only fly higher and faster but also redefine how the world travels — safely, efficiently, and sustainably.